Single Phase Motors

Single-phase motors are Motor Types that use an alternating current (AC) supply. The

alternating current in the main winding generates a magnetic field around the

rotor, resulting in torque. The rotor then rotates in the opposite direction to

the flux created by the main flux. The rotor's torque develops when the rotor

is nearing the speed of the backward rotating phasor.

Single-phase motors incorporate a starting winding, a starting switch,

and an electrolytic capacitor. When the motor is powered on, the capacitor

discharges into the start winding, giving the motor a start. The starting

switch removes the capacitor when the rotor reaches about 75%-80% of its

maximum speed, allowing the running winding to ramp up to full operational

speed.

Brushless DC Motors

Brushless DC motors are electric motors that operate without a brush.

They are also known as electronically commutated motors or synchronous DC

motors. Brushless DC motors operate on a direct current electric power supply.

Unlike their synchronous counterparts, they don't need any mechanical brushes

to maintain torque.

Brushless DC motors are used in many electrical products. They are

common in laser printers, as well as in drones, and they can be used to control

propellers and gimbals. They can also be used as powerful tools for turning

blades and screwdrivers. These motors can cut down on product development costs

and increase energy efficiency. The ability to quickly turn the disk is a

crucial function for precision devices.

Linear Motors

Linear motors work by using an electric force to move a device along a

long length. A linear motor has an unrolled stator and rotor that produce a

force along its length. Although it might seem that linear motors only move in

one direction, there are several variations of this motor type.

Modern linear motors feature a highly optimised iron core design and a

low-cogging performance. Linear motors may also be configured with magnets that

are set at a small angle to the direction of motion, resulting in smoother

movement.

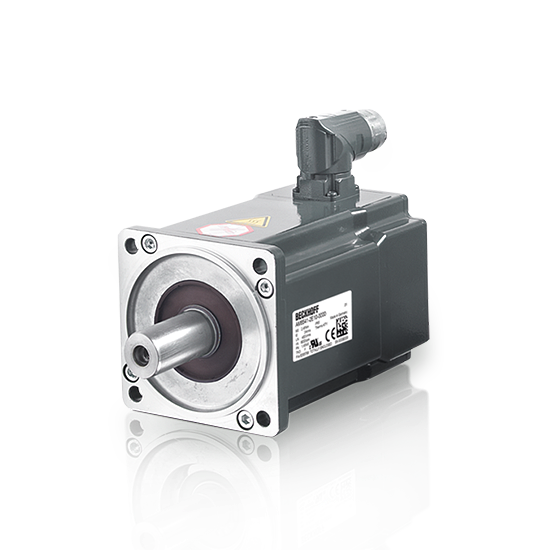

Servomotors

Servomotors are actuators that control the position of an object by

varying the input voltage levels. They are used in many different applications,

from robotic systems to cameras. They are also used in antenna positioning

systems, providing accurate antenna elevation and position. The positioning of

an object is also controlled by a feedback potentiometer, which changes the

position of the motor as it responds to a changing voltage.

Servomotors are the most common type of motor. Their shafts are designed

to rotate in a 180-degree range, and they contain a rotation sensor.

Servomotors are also commonly used in toys and radio-controlled vehicles. They

also provide powerful and precise position sensing in robotics.

Cumulative Compound Motors

Cumulative compound motors combine the advantages of a shunt motor and a

series motor. These types of motors can start at full speed with a heavy load

attached, but they are not ideal for controlling speed. Fortunately, cumulative

motors combine the features of both types of motors, so they're appropriate for

many applications.

In addition to variable speeds and torque, cumulative compound motors

can be controlled by changing voltage. These motors are useful for machines

with high torque, heavy loads, and varying pressure. This makes them a good

choice for cutting machines, stamping presses, and punches.

Servomotors with Integral Brakes

Servomotors with integral brakes are commonly used in robotics and

machine vision applications. These systems offer a range of options for

mounting and torque range. They can be easily mounted and have high torsional

rigidity, making them suitable for any mounting style. Another major advantage

is that they do not require system winding up. They also can hold a machined

end of a ball screw.

When choosing a servomotor with an integrated brake, the operating

conditions and application requirements must be considered. For example, the

brake should be able to generate sufficient static torque for the application.

In addition, it must be able to maintain the shaft's position under all

circumstances. Moreover, the orientation of the motor should be considered,

since it may affect the brake load.

Repulsion Motors

A repulsion motor is a type of electric motor that runs on alternating

current (AC). It was once the standard traction motor for electric trains but

has since been superseded by other types of motors. A repulsion motor is

considered a single-phase motor, meaning that it works on one phase of the AC

power.

A repulsion motor's starting torque depends on the position of the brushes inside the commutator. The brushes are shifted clockwise or counterclockwise relative to the main magnetic axis, and they are shorted together to form a field that generates torque. A brush shift of 45 degrees will produce maximum torque. This brush shift also allows the speed of the repulsion motor to be controlled.

Post a Comment